Product Description

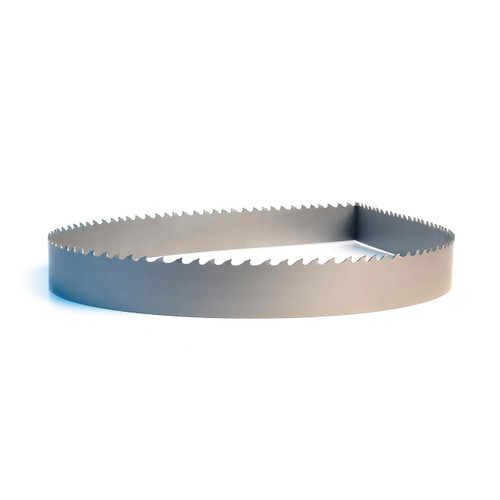

PRECISION TRIPLE CHIP GRIND

Smooth cuts, excellent finish

HIGH PERFORMANCE BACKING STEEL

Excellent fatigue life

GENERAL PURPOSE BLADE

Perfect for cutting of a wide variety of materials

Tri-Master: Conquer High-Strength Steels with This Premium Blade

The Tri-Master bandsaw blade is a top-of-the-line blade designed to deliver exceptional performance and extended service life when cutting high-strength steels and challenging alloys.

Key Features of the Tri-Master:

- Superior Strength and Durability: Engineered with high-grade carbide tips and a high-performance backing steel, the Tri-Master tackles tough jobs with ease while minimizing blade wear.

- Reduced Pinch and Breakage: The innovative tooth design minimizes pinching and breakage during cuts, especially when working with high-stress metals.

- Versatility for Various High-Strength Materials: Suitable for cutting a broad range of high-strength steels, nickel alloys, titanium, and other demanding materials.

- Available in Multiple Sizes: Offered in a variety of lengths and widths to suit your specific cutting needs.

Elevate your metal cutting capabilities with the Tri-Master bandsaw blade. Its superior strength, durability, resistance to pinching, and versatility across high-strength materials make it a valuable asset for professional machinists and fabrication shops.

Specifications

| TOOTH FORM WIDTH X THICKNESS | VARI-TOOTH® TPI | ||||

|---|---|---|---|---|---|

| IN | MM | 2/3 | 3/4 | 3 | |

| 3/8 x .032 | 9.5 x 0.80 | ◆ | |||

| 1/2 x .025 | 12.7 x 0.64 | ◆ | |||

| 3/4 x .035 | 19 x 0.90 | ◆ | |||

| 1 x .035 | 27 x 0.90 | ◆ | ◆ | ◆ | |

| 1-1/4 x .042 | 34 x 1.07 | ◆ | ◆ | ◆ | |

| 1-1/2 x .050 | 41 x 1.27 | ◆ | ◆ | ||

Applications

Primary

Solid Square / Rectangle

Sold Round

Plate

Secondary

Tubes

Case-Hardened Tubes

Materials

- Aluminum / Non-Ferrous

- Carbon Steels

- Wood

Secondary

- Alloy Steels

- Mold Steels

- Structural Steels

- Tool Steels

- Stainless Steels

SQUARE/RECTANGLE SOLID

LOCATE WIDTH OF CUT (W)

| WIDTH OF CUT | ||

|---|---|---|

| IN | MM | TPI |

| .1 | 2.5 | 14/18 |

| .2 | 5 | 14/18 |

| .3 | 7.5 | 10/14 |

| .4 | 10 | 10/14 |

| .5 | 12.5 | 8/12 |

| .6 | 15 | 8/12 |

| .7 | 17.5 | 6/10 |

| .8 | 20 | 6/10 |

| .9 | 22.5 | 6/8 5/8 |

| 1 | 25 | 6/8 5/8 |

| 2 | 50 | 4/6 |

| 5 | 125 | 3/4 |

| 10 | 250 | 2/3 |

| 15 | 375 | 1.5/2.0 1.4/2.0 |

| 20 | 500 | 1.0/1.3 |

| 25 | 675 | 1.0/1.3 |

| 30 | 750 | 1.0/1.3 |

| 35 | 875 | 0/7/1.0 |

| 40 | 1000 | 0/7/1.0 |

| 45 | 1125 | 0/7/1.0 |

| 50 | 1250 | 0/7/1.0 |

ROUND SOLID

LOCATE DIAMETER OF CUT (D)

| DIAMETER OF CUT | ||

|---|---|---|

| IN | MM | TPI |

| .1 | 2.5 | 14/18 |

| .2 | 5 | 14/18 |

| .3 | 7.5 | 10/14 |

| .4 | 10 | 8/12 |

| .5 | 12.5 | 6/10 |

| .6 | 15 | 6/10 |

| .7 | 17.5 | 6/10 |

| .8 | 20 | 6/8 5/8 |

| .9 | 22.5 | 6/8 5/8 |

| 1 | 25 | 6/8 5/8 |

| 2 | 50 | 4/6 |

| 5 | 125 | 3/4 |

| 10 | 250 | 2/3 |

| 15 | 375 | 1.5/2.0 1.4/2.0 |

| 20 | 500 | 1.0/1.3 |

| 25 | 675 | 1.0/1.3 |

| 30 | 750 | 1.0/1.3 |

| 35 | 875 | 1.0/1.3 |

| 40 | 1000 | 0/7/1.0 |

| 45 | 1125 | 0/7/1.0 |

| 50 | 1250 | 0/7/1.0 |

TUBING/PIPE/STRUCTURALS

LOCATE WALL THICKNESS (T)

| WALL THICKNESS | ||

|---|---|---|

| IN | MM | TPI |

| .5 | 1.25 | 14/18 |

| .10 | 2.5 | 10/14 |

| .15 | 3.75 | 8/12 |

| .20 | 5 | 6/10 |

| .25 | 6.25 | 6/8 5/8 |

| .30 | 7.5 | 6/8 5/8 |

| .40 | 10 | 4/6 |

| .50 | 12.5 | 4/6 |

| .60 | 15 | 4/6 |

| .70 | 17.5 | 3/4 |

| .80 | 20 | 3/4 |

| .90 | 22.5 | 3/4 |

| 1 | 25 | 3/4 |

| 1.5 | 37.5 | 2/3 |

| 2 | 50 | 2/3 |